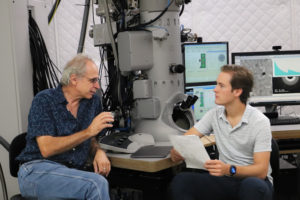

Prof. Gerd Duscher with Austin Houston MSE 2022

By Austin Houston. Photography by Randall Brown.

Professor Gerd Duscher joined the MSE faculty in 2008 after building international experience in materials science and engineering. Austin Houston is an MSE graduate student who works with Duscher’s research group at IAMM, UT’s Institute for Advanced Materials and Manufacturing.

Houston: One of the first times we met, you told me some crazy stories about being a mountain guide when you were younger. Even then you loved sharing what you know. Did you always see yourself being a professor?

Duscher: Since I started my master’s, I knew I wanted to be a professor. Before that, not! I had no specific academic ambitions and wanted to work in industry. When I was looking for a master’s thesis, the microscopy group at the University of Regensburg was playing Star Trek with a very technical-looking electron microscope with lots of knobs, and I thought, “That is an environment I want to do my master’s in and that made research interesting.”

Houston: What do you enjoy about being a part of the UT community?

Duscher: I like most that it is very collegial and everybody is really, very dedicated—in administration and in research. My role at UT is to operate the microscopy facility and serve the various research needs of students, making sure that as many students as possible may become experts on these high-end research instruments. I feel like that is the best way I can give back to the community.

Houston: What do you image will be the biggest advancement in electron microscopy in the future?

Duscher: The biggest in my career has been the aberration corrector, which revolutionized electron microscopy. We are at a place where spatial resolution is no longer a limiting factor. I expect the usage of electron microscopy will get easier and easier, which puts the focus on designing experiments that allow utilizing multiple signals simultaneously and synergistically.

Houston: The new TEM [transmission electron microscope] here at IAMM is stirring up some excitement. Can you tell me more about why this microscope is so unique?

Duscher: This microscope has state-of-the art spatial resolution and detectors which allow us to look at materials and their defects with unprecedented precision. This is important because, in some materials, defects carry a quantum state. To utilize and engineer these materials, one must know what and where an individual defect is. Also, the properties of structural materials, like aluminum alloys, are governed by defects. The new microscope lets us not only see atomic resolution but see what elements the atoms are and how they are bonded. It is really a big jump in technology.

Houston: You also have a joint position at ORNL. What drew you to ORNL and what role does this play in your research?

Duscher: The whole reason I originally came to the United States was for the microscopes at ORNL. The microscopes and instruments there are very specialized and built for scientists, whereas the tools we have at UT are more general purpose and geared towards educating students. My goal is always striving to teach students a variety of techniques which enables them